Key in a search term below to search our website.

Key in a search term below to search our website.

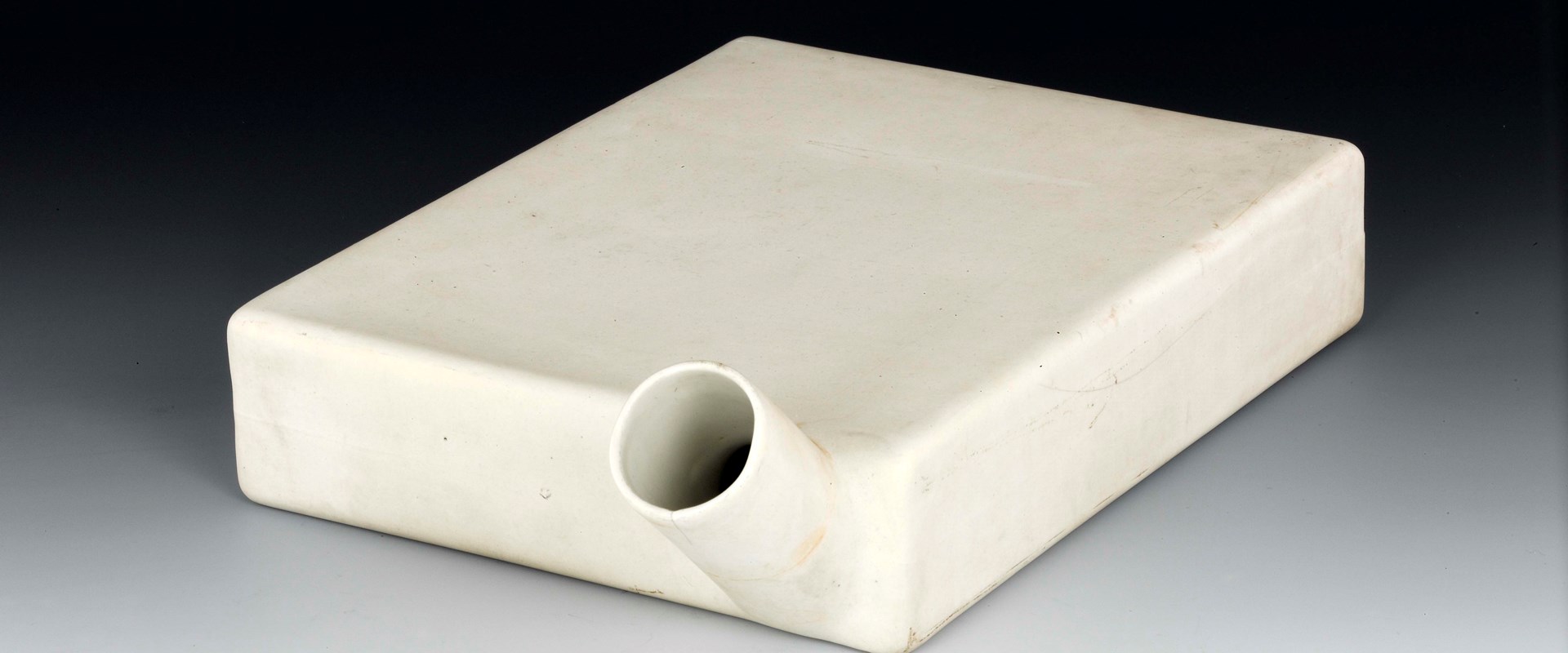

This simple looking object made it possible for the first clinical trials and batch production of penicillin to take place. Its design marks a significant milestone in the history of medicine.

Date

1940

Made in

Burslem, Staffordshire, England

Designed by

Dr Norman George Heatley (1911-2004)

Made by

James Macintyre and Co. Ltd

Made from

Slip cast ceramic

Acquired

Gifted to National Museums Scotland.

Museum reference

On display

Discoveries, Level 1, National Museum of Scotland

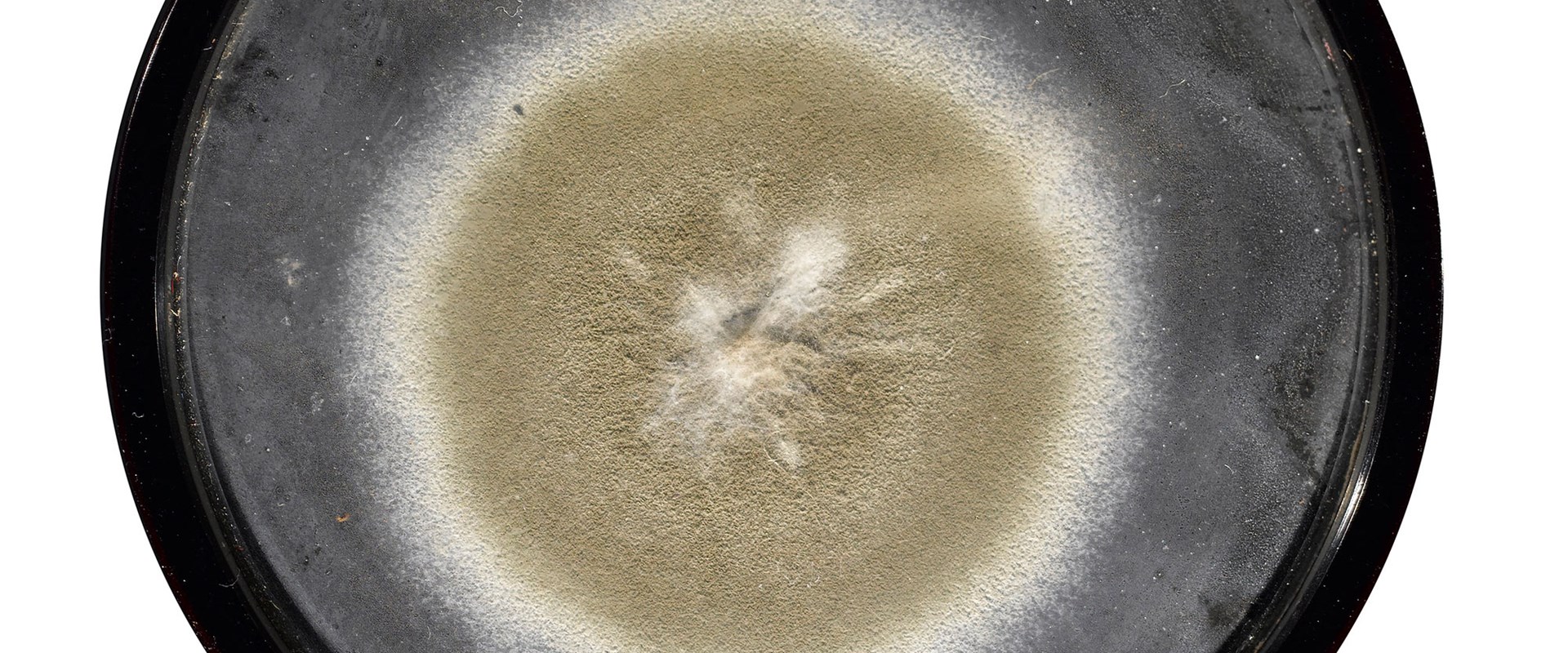

In 1928, Sir Alexander Fleming made a discovery by accident when cleaning up a set of glass plates which had been used to grow a bacterium. He noticed that a mould growing on one of these plates, had inhibited the growth of the bacteria. He followed this observation up by growing the mould in a broth made of beef heart.

Fleming published his research in 1929 and two of his key conclusions were that this ‘mould juice’ could be used to remove contaminants from bacterial cultures and it could also be used as an antiseptic, to treat the surface of infected wounds.

“This observation of the Penicillium notatum mould growing on the Staphylococcus aureus culture plate led to the future development of the substance we now call penicillin, a drug which has since saved millions of lives.

Sir Alexander Fleming won many awards and he often liked to give something in return. He had samples of penicillin mould mounted in frames to give as gifts and this specimen is inscribed on the back by Alexander Fleming.

Ten years later, in 1938, Howard W Florey, Professor of Pathology at the University of Oxford, was looking for a substantial project for his group of research workers (which initially included Ernst Boris Chain and Norman Heatley). He decided to research the phenomenon of ‘antibiosis’ (the process whereby micro-organisms produce substances that kill or inhibit other micro-organisms). From compiling a list of about 200 known examples of antibiosis, Florey and Chain decided to investigate just three. The first of this three was the substance produced by Penicillium notatum, described by Alexander Fleming.

Above: Group portrait (back row, left to right) S. Waksman, H. Florey, J. Trefouel, E. Chain, A. Gratia, (front row left to right) P. Fredericq and Maurice Welsch. Wellcome Library, London.

Dr Norman George Heatley, played a vital role in this work. His task was to produce as much ‘mould juice’ as possible for the others to study. He also devised the essential step that allowed the partial purification of the drug penicillin, built the apparatus to carry out this purification process, and developed the method to measure how much of the drug penicillin was present in any sample. This method forms the basis of the assessment of the sensitivity of micro-organisms to antibiotics to this day.

By the time the research was under way, it was wartime. Equipment was difficult to get hold of and air raids a constant threat. To produce the required 'mould juice' Heatley cultured Fleming's strain of Penicillium notatum in a variety of vessels with a large surface area, including pie dishes, biscuit tins (obtained from Huntley & Palmers of Reading), bottles, petrol cans and bed pans. His preferred containers were 16 lidded enamel bed pans obtained from the Radcliffe Infirmary. Enough crude penicillin powder had been prepared by May 1940 to allow animal testing. This was successful and the next step was to prepare for clinical human trials on human patients.

Above: Bedpans are used by people at home or in hospital who are bed bound by illness and unable to use an outside toilet or chamber pot. The handle is hollow, possibly for urination as well as allowing the urine to be poured out after use. Science Museum, London, Wellcome Images.

Many more culture vessels were required to produce much larger quantities of mould broth needed to make enough crude penicillin powder to treat the first human patients. The war made finding them very difficult. Heatley’s preferred bed pan became unavailable, a glass design would take too long to manufacture and so a pottery vessel was suggested.

Above: This is the initial sketch for his pottery culture flask designed by Dr Norman G. Heatley. Wellcome Library, London

The rectangular profile of this culture vessel was deemed the most efficient form, as it meant they could be stacked upright for sterilisation and horizontally for incubation. The inside is glazed to make it watertight, whilst the outside was left unglazed to prevent slippage during handling and to reduce production costs. Within 2 months of Heatley’s initial sketch the first batch of 174 had been made and half of them were seeded with spores of the fungus on 25 December 1940.

Above: The flasks being incubated at 24’ C in the animal operating theatre of the Sir William Dunn School of Pathology. Florey et al, Antibiotics, 1949, Oxford University Press. By permission of the Museum of the History of Science, University of Oxford

In total, 700 vessels were made by James Macintyre and Co. Ltd at 10 shillings (50p), each. The maximum output of the facility in the Dunn School was 500 litres of mould broth per week and about 2000 litres of mould broth were needed to produce enough crude penicillin powder to treat one patient. The penicillin made here was used to treat the first six patients in the Radcliffe Infirmary in Oxford in 1941.

“In all, the initial animal tests and the treatment of the first six patients used about four million units of penicillin (which is now regarded as a reasonable daily dose for one individual).

Because the yield of penicillin was so poor it was in very short supply. As penicillin is excreted unchanged through the kidneys, in order to make the most of the very short supplies, the urine of patients being treated with it was collected and each evening it was taken back to the Dunn School for the penicillin to be extracted from it for re-use. This brings us back, full circle, to bedpans.

This pewter bedpan example is punched with the maker’s name, “Deverres”, and the place name, “Caen, France”, and is said to have been used in a French hospital called Maison Leseigner. 1750-1890. Science Museum, London, Wellcome Images

As British pharmaceutical firms were unable, because of the war, to take on the production of penicillin. The results obtained from the clinical trials in Oxford were used to persuade the American government to assist in the development of the production of penicillin on an industrial scale.

“Penicillin became one of the first successful drugs to treat bacterial infections, saving thousands of lives during World War II.

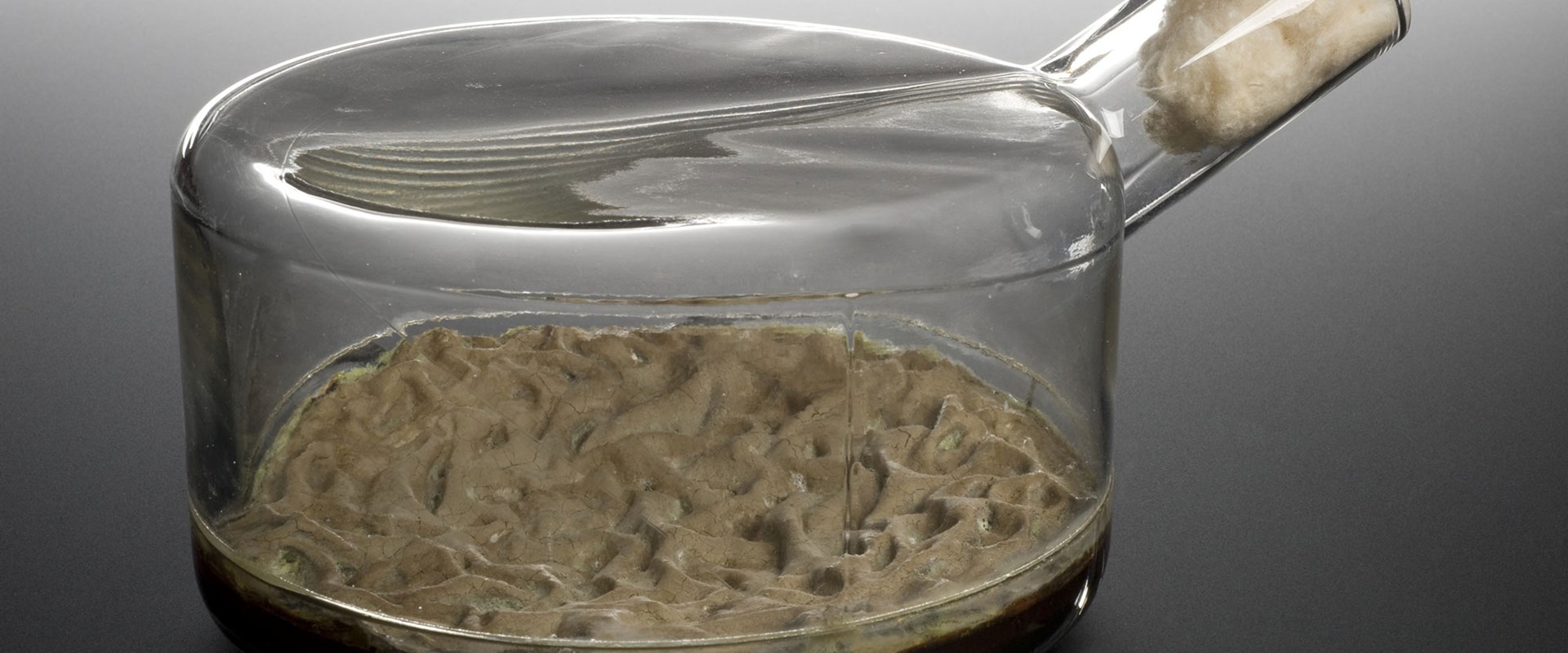

Thousands of glass fermentation vessels like this one were used in Glaxo (now GlaxoSmithKline) laboratories to produce penicillin. The penicillium mould was grown on the surface of a liquid filled with all the nutrients it needed. This approach was superseded by the method of growing the mould within large industrial fermenters. 1940-1945 Wellcome Library, London