Key in a search term below to search our website.

Key in a search term below to search our website.

Discover what this historic tool can tell us about the story of machinery and industry in Scotland.

Date

c.1916

Made in

Johnstone, Renfrewshire, Scotland

Made by

John Lang and sons

Made from

Cast iron, mild steel, part painted grey

Dimensions

Height 225cm, width 97cm, depth 122cm

Museum reference

On display

Workshop of the World, Level 4, National Museum of Scotland

Did you know?

Lathes have been in use since Ancient Egyptian times, and were also used in Assyria, Greece and across the Roman Empire.

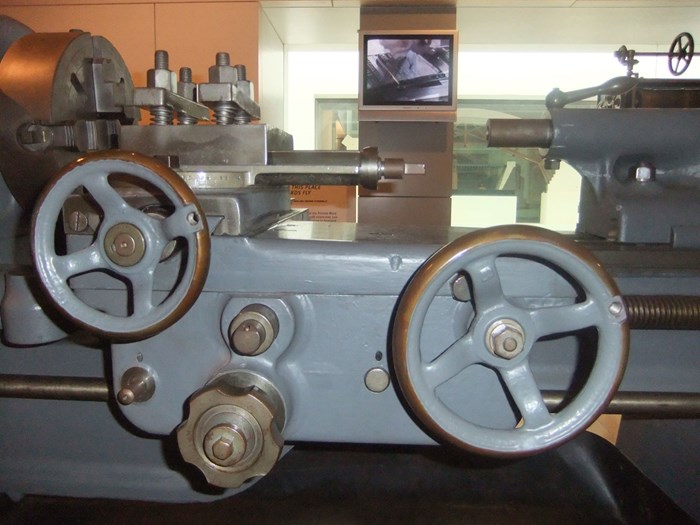

Above: The lathe on display in the National Museum of Scotland.

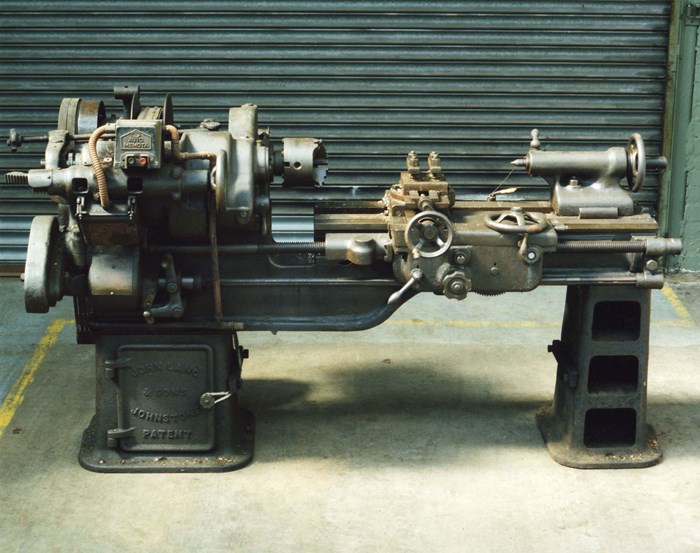

Our Workshop of the World gallery celebrates Scotland’s reputation as a pioneering industrial nation. At the far end of the gallery, you’ll find an impressive piece of machinery that symbolises the innovation and energy of Scottish industry: a lathe made around 1916 by John Lang and Sons, an engineering company based in Renfrewshire.

John Lang was one of the leading manufacturers of machine tools, especially lathes, in the late 19th and early 20th centuries, with customers across the world, from Europe to Hong Kong to Russia.

Above: The John Lang lathe.

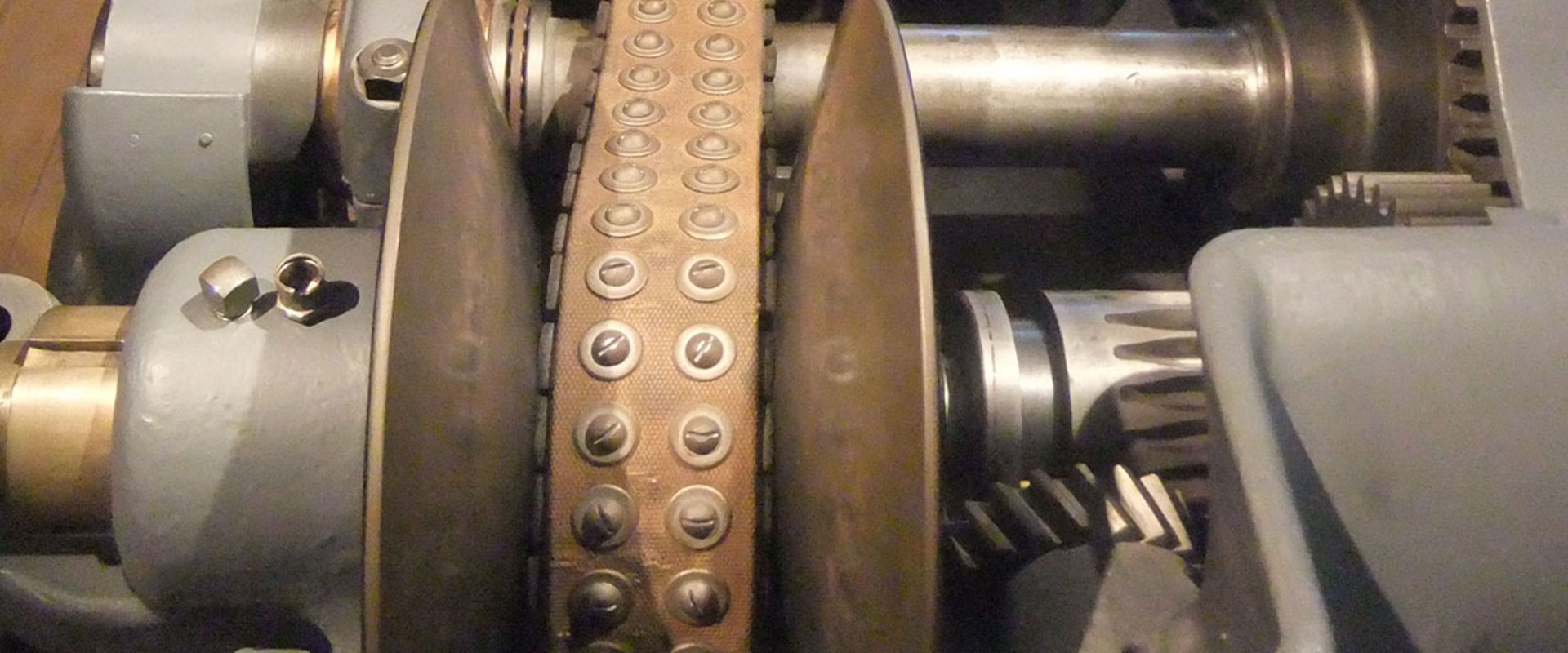

A lathe is a machine tool used in metal working, woodwork, pottery and glass making. Lathes are used to make symmetrical objects. The material to be worked is turned on a spindle driven manually, by water or steam or by an electric motor, and is shaped by a cutting tool mounted on the lathe. A potter’s wheel is a simple example of a lathe: the clay spins round on the wheel, while the potter shapes it with their hands.

By the early 20th century, when our machine was made, lathes had become complex tools, masterpieces of engineering developed and adapted to complete a huge range of industrial tasks. Lathes like the one in the museum were used for a wide range of metal working and could operate at various speeds to create a variety of products. They could be found on local farms, Glasgow shipyards or railway works in Australia.

There are lots of ways we can discover more about how old machine tools such as the John Lang lathe were used in practice. During the 19th and early 20th century, many books and journals were published about machine tools, using photographs and diagrams to explain how they worked. These books were not just aimed at factory workers, but at beginners who wished to buy and use these machines at home for a spot of turn-of-the-century DIY!

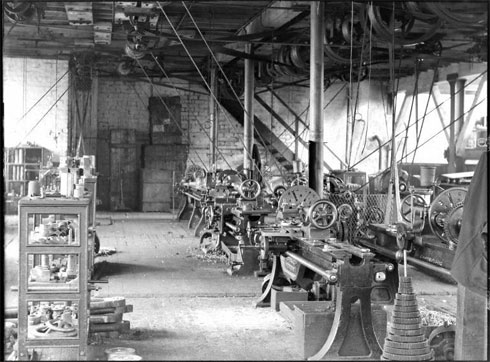

Operating manuals and company photographs are another useful resource. The archives of the John Lang Works contain hundreds of photos showing how machine tools were manufactured and how the finished products worked. Often these photos reveal details that could be missed from a manual. For example, some workers keeping their feet warmer in winter by standing on wooden pallets when operating machinery.

Above: Machines on the floor of a munitions factory, Renfrewshire, c. 1915.

However, there is only so much we can learn from words and diagrams. Some skills, such as the ability to hear when machinery is malfunctioning, or feel the temperature rise, can only be learned through experience. So to really understand how machinery worked in the past, we need to experience working historic machine tools firsthand.

Nowadays, our curators and conservators still work with some of our historic machine tools for restoration purposes and to provide public demonstrations. By using the machines, we can learn things that would have been obvious to the original operators, but which might now be forgotten, such as what kind of clothing to wear or how best to stand when operating the machine.

Machine tools were shaped through the knowledge and skills of the engineers who made them and the workers who operated them. By looking at historic machine tools today, we can learn more about these skills, and come to appreciate the ingenuity and expertise with which they were made and used.